ATV, or all-terrain vehicle, can drive under different kinds of complex terrain, such as beach, swamp and desert, because of its special structure and off-road performance. Due to the adverse driving conditions, the requirement of parts is extremely strict. ATV axle is an important transmission component for front-wheel drive and all-wheel drive ATV.

During the metal processing procedure, the material needs to withstand complex stress status. Most of the stress fracture risk occurs in weak parts where forces are concentrated. We combined previous failure situations and FEMA Analysis, and came out with a failure solution manual in all aspects of the manufacturing process, applied with our unique SURE-CHAMFERTM technology to systematically eliminate the stress issue during metal processing. This technique effectively reduced the fracture risk.

Through research, we found that most ATV axles failed from the aging and breakage of the C.V. boot. Our development focused on the aging of C.V. boot in tough temperature conditions, for example the hot and dry climate in Middle East and the deep freeze climate of Alaska, U.S.A. To solve the problem of cracking and aging of C.V. boot in tough temperature condition (-40 ℃-100 ℃), we developed SURE-LIMIT technology with special formulated materials. It effectively solve the aging of C.V. boot under extreme temperature conditions.

Patent No. ZL 201020203615.1 for large swing angle ATV axle with spline sliding. It enhanced the maximum wing angle of the ATV axle to 48 degrees, effectively enhance the performance of the ATV.

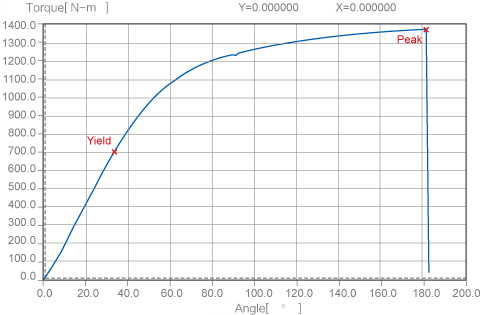

Every new product goes through various systematic and rigorous testing before it launches to the market.